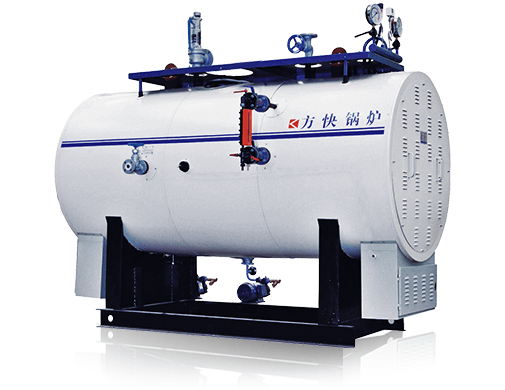

Газ(масло) Водотрубный паровой котел на огневом топливе Котел имеет двухбарабанную продольную конструкцию типа «D».; вода, по трубе течет пар или пароводяная смесь; пламя горит и дымовые газы выходят за пределы трубы, формирование чрезвычайно быстрого пароводяного потока и отличной системы циркуляции воды. Скорость поглощения тепла котла и тепловой КПД высоки.

Номинальная тепловая мощность: ≥10т/ч

Номинальная тепловая эффективность: 100-104%

Давление: ≤2,5 МПа

Доступное топливо: дизель, тяжелое масло, природный газ, городской газ, сжиженный газ, так далее.

Преимущества газа(масло) Водотрубный паровой котел

- Качество котла хорошееБолее 95% сварочного оборудования используется. Каждый котел проходит испытания и закалку перед отправкой с завода. Квалифицированная скорость осмотра 100%.

- Эффективная теплопередачаБарабан не нагревается напрямую, а трубка, содержащая водяной пар, помещается в печь и дымоход в качестве поверхности нагрева для повышения эффективности теплопередачи..

- Удовлетворить большие требования к испарению Печь размещена вне цилиндра, и объем печи может быть большим или маленьким, чтобы удовлетворить требования горения и большого испарения.

- Небольшое воздействие стихииСпециальное расположение водопровода увеличивает поверхность нагрева, но количество котловой воды не много. В случае бедствия, степень поражения небольшая.

Газ(масло) Fired Water Tube Steam Boilers are an innovative and reliable solution for producing steam in industrial settings. They are commonly used in power generation plants, chemical processing facilities, and refineries, среди прочего. With their high efficiency, safety features, и универсальность, газ(масло) fired water tube steam boilers have become a popular choice for many industries.

If you’re considering investing in a gas(масло) fired water tube steam boiler, this article will provide you with a comprehensive overview of their features, преимущества, и приложения.

The Components of a Gas(масло) Водотрубный паровой котел

Burner: The burner is responsible for supplying fuel to the combustion chamber, where it is ignited and produces heat. Газ(масло) fired water tube steam boilers can use natural gas, пропан, дизель, or other fuels, depending on the application.

Heat Exchanger: The heat exchanger transfers heat from the combustion gases to the water. Газ(масло) fired water tube steam boilers use a series of tubes that are surrounded by hot gases, which heat the water inside the tubes.

Water Tank: The water tank stores the water that will be heated and transformed into steam. It is important to maintain the water level within the tank to prevent damage to the boiler.

Steam Drum: The steam drum is where the steam is collected and distributed to the rest of the system.

The Steam Generation Process

The steam generation process begins with the burner igniting the fuel and producing heat. The hot gases produced by the burner flow through the heat exchanger, where they transfer their heat to the water inside the tubes. As the water absorbs the heat, it begins to boil and produce steam. The steam rises and enters the steam drum, where it is collected and distributed to the rest of the system.

Преимущества газа(масло) Fired Water Tube Steam Boilers

Энергоэффективность

Газ(масло) fired water tube steam boilers are known for their high energy efficiency. They use less fuel to produce the same amount of steam as traditional boilers, which translates into lower operating costs and reduced carbon emissions. Кроме того, газ(масло) fired water tube steam boilers are designed to recover heat from the combustion gases, further improving their efficiency.

Durability and Longevity

Газ(масло) fired water tube steam boilers are built to withstand harsh industrial environments. They are made of high-quality materials that can withstand extreme temperatures, давление, and corrosive substances. Более того, газ(масло) fired water tube steam boilers have fewer moving parts than traditional boilers, reducing the risk of mechanical failure and prolonging their lifespan.

Низкие расходы

Газ(масло) fired water tube steam boilers require less maintenance than other types of boilers. They have fewer components that need to be checked or replaced, which reduces downtime and maintenance costs. Кроме того, газ(масло) fired water tube steam boilers are equipped with safety features that prevent them from overheating or malfunctioning, further reducing the need for maintenance.

Applications of Gas(масло) Fired Water Tube Steam Boilers

Power Generation Plants

Газ(масло) fired water tube steam boilers are commonly used in power generation plants to produce steam that drives turbines and generates electricity. They are preferred over other types of boilers due to their high efficiency and low emissions.

Chemical Processing Facilities

Газ(масло) fired water tube steam boilers are also used in chemical processing facilities to produce steam for various processes, например, отопление, дистилляция, and sterilization. They are ideal for these applications due to their high energy efficiency and durability.

Refineries

Газ(масло) fired water tube steam boilers are widely used in refineries to produce steam that is used in various processes, such as crude oil distillation, hydrogen production, and wastewater treatment. They are preferred over other types of boilers due to their reliability, энергоэффективность, and low emissions.

Food and Beverage Industry

Газ(масло) fired water tube steam boilers are also used in the food and beverage industry to sterilize equipment, cook food, and pasteurize beverages. They are preferred over other types of boilers due to their high energy efficiency, низкие выбросы, and compliance with food safety regulations.

FAQs about Gas(масло) Fired Water Tube Steam Boilers

Вопрос: Are gas(масло) fired water tube steam boilers more expensive than traditional boilers?

А: Газ(масло) fired water tube steam boilers may have a higher upfront cost than traditional boilers, but their high energy efficiency and low maintenance requirements make them a cost-effective solution in the long run.

Вопрос: Can gas(масло) fired water tube steam boilers use renewable fuels?

А: Да, газ(масло) fired water tube steam boilers can be adapted to use renewable fuels such as biomass, biogas, and hydrogen, depending on the application.

Вопрос: What safety features do gas(масло) fired water tube steam boilers have?

А: Газ(масло) fired water tube steam boilers are equipped with safety features such as pressure relief valves, water level sensors, and flame failure protection systems to prevent them from overheating or malfunctioning.

Вывод

Газ(масло) fired water tube steam boilers are an innovative and reliable solution for producing steam in industrial settings. They are preferred over traditional boilers due to their high energy efficiency, долговечность, and low emissions. Газ(масло) fired water tube steam boilers are widely used in power generation plants, chemical processing facilities, нефтеперерабатывающие заводы, and the food and beverage industry, среди прочего. If you’re considering investing in a gas(масло) fired water tube steam boiler, make sure to choose a reputable manufacturer and consult with a professional to ensure that you select the right boiler for your specific needs.

Электрический водогрейный котел

Электрический водогрейный котел  Электрический паровой котел

Электрический паровой котел  Газовый водогрейный котел V6

Газовый водогрейный котел V6  2023 Руководство по ценам на газовые котлы | Сравнение затрат на домашний газовый котел

2023 Руководство по ценам на газовые котлы | Сравнение затрат на домашний газовый котел  Лучшие котлы для газификации древесины на продажу | Руководство по покупке

Лучшие котлы для газификации древесины на продажу | Руководство по покупке  Цены на электрические комбинированные котлы | 2023 Руководство по покупке

Цены на электрические комбинированные котлы | 2023 Руководство по покупке